High-Performance Cemented Sleeve well Completions systems.

Simple,Reliable,Flexible

Completion Energy Specializes in Cemented Sleeve Completions to increase efficiency and make better wells

Facing so many improvements in the completion of oil and gas wells, over the last 20 years, and being aware of the complexity of the manufacturing of the equipment, Completion Energy is keeping abreast with the technological innovations. One of the particular areas reflecting this improve is reflected in the cemented sleeve completion designs in which we are considered one of the pioneers allowing us to assure our customers can confidently deploy them in the challenging reservoir conditions facing those applications.

To respond to the complexity of the engineering and manufacturing processes, Completion Energy seeks solutions to monitor and control the continuous operational processes, particularly in the manufacturing of threads, port sizes and burst pressures. This way, it enables our completion systems and tools to meet the demanding expectations our customers are setting with our products.

Feel free to choose an option from the listing below to learn details about our cemented sleeve completion systems and tools, or contact us for more information.

MULTIFRAC™ SYSTEM

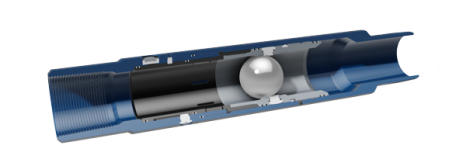

This limited-entry, ball-drop system combines our patented MultiFrac, hydro-mechanical sleeves with the patent-pending BurstPoint™ ports to improve the placement of the stimulation treatment which leads to improved well productivity and so, NPVs.

ENERFRAC™ SYSTEM

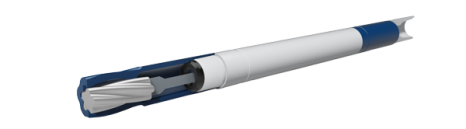

This single-entry, ball-drop system uses our patented EnerFrac hydro-mechanical sleeves that allows the stimulation of individual stages at high rate conditions.

INITIATION ASSEMBLY

Our Cemented Initiation Assembly enables operators to start the stimulation operations from the toe and perform a full first-stage limited-entry stimulation in cemented wellbores.

BALL-DROP CEMENTED INITIATION SUB

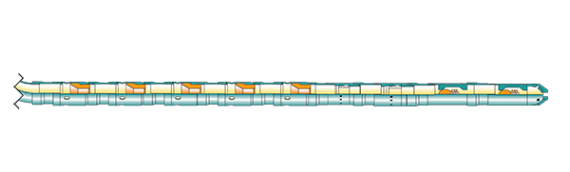

MultiFrac™ System

Increases Fracture Density, Reducing Time and Cost. (Improving NPVs)

Overview

APPLICATION

- Single design for open hole or cemented liner installations

- Cluster (batch) stimulation of multiple stages at the same time

- Ability to stimulate 150+ stages, if required

FEATURES AND BENEFITS

- Get faster completion times due to limited-entry stimulation technique of multiple stages with a single treatment from surface

- One ball activates multiple MultiFrac sleeves, which allows higher stage density within the same wellbore section

- Our multiFrac sleeves have no communication with the annulus until the BurstPoint port rupture pressure is reached

- The BurstPoint port inserts prevent erosion, allowing cluster efficiency of ≥90% throughout the treatment stage

- The BurstPoint ports can be sized to control the fracture fluid rate, on a per-sleeve basis

- The adjustable stimulation volumes enable true limited-entry operations

- There are positive surface indicators of multiple entry points, providing real-time parameters operational data

- The enhanced fracture network leads to an increased wellbore conductivity (increased well productivity)

- The surface pressure indications are an accurate monitoring system of the tool performance

- The rugged design for enhanced reliability allow:

- Rotation to bottom, if required

- Handling the high torque capabilities of all premium and semi-premium connections

- The ball seats are designed for quick mill-out times

EnerFrac™ System

Overview

Our Completion Energy Completion’s EnerFrac™ single-entry, ball-drop system uses the patented EnerFrac hydro-mechanical sleeves that are designed to stimulate individual stages at high rate. The EnerFrac sleeves feature a patent-pending BurstPoint™ port, which fully opens by increasing hydraulic pressure, after the sleeve is shifted by an activation ball. This operation instantaneously releases the energy of the hydraulic pressure stored in the tubing to provide a more deepening treatment, resulting in a higher fracture volume network, resulting in a remarkable fracture productivity increase.

A no-communication condition with the wellbore exists until the BurstPoint ports are opened, which is then followed by the stimulation process. This “on-the-fly” operation technique enables a quick completion of the stimulation process, increasing the fracture efficiency and allowing reduction of costs (increased NPVs)

APPLICATION

- A single design for open hole or cemented liner installations options

- Applicable in conventional and acid fracturing techniques

- Stimulation of individual stages at high flow rates

FEATURES AND BENEFITS

- The BurstPoint ports prevent cement from entering the sleeve from the annulus, enabling unprecedented reliability in a cemented sliding sleeve application

- The surface pressure indications are an accurate monitor of the tool performance during the treatment

- A rugged design for enhanced reliability allow:

- Rotation to bottom, if required

- Designed to handle the high torque capabilities of all premium and semi-premium connections

- The ball seats are designed to attain quick mill-out times

Initiation Assembly

Overview

Our Completion Energy Cemented Initiation Assembly enables operators to initiate stimulation operations through the toe and perform a full first-stage limited-entry stimulation in cemented wellbores. By combining Tartan’s patented Cemented Initiation Sub (CIS) and MultiFrac™ limited entry sleeves, the Initiation Assembly can be customized to the desired stimulation rate.

Since all tools — including the CIS — are incorporated into the stage design, no rock will go untreated. Because the toe stage will have the same number of points as a regular entry stage, there is no need to pump a smaller stage for the toe of the well or pump guns down to perforate the remainder of the toe/first stage.

The CIS and MultiFrac sleeves feature patent-pending BurstPoint™ ports that improve stimulation treatment placement and effectiveness and keep the system internals completely closed during installation and the cementing process, eliminating the risk of debris and cement invasion.

The MultiFrac hydro-mechanical sleeves are activated with standard or dissolvable balls and enable cluster stimulation by opening multiple sleeves with one ball. Once the sleeves are shifted, liner pressure is increased to fully open the BurstPoint ports to achieve calculated limited entry stimulation with +90% cluster efficiency.

APPLICATION

- Eliminates coiled tubing and perforating costs for first stage initiation in cemented wellbores

- Enables full stimulation and production of the toe zone

- Efficient cluster stimulation of lower zones in extended reach laterals

- The Ball-drop CIS option provides the ability to pressure test the liner prior to any stimulation operations

FEATURES AND BENEFITS

- Provides increased operational efficiency resulting in reduced costs

- The BurstPoint ports can be sized to control the stimulation fluid rate on a per sleeve basis

- The BurstPoint port inserts prevent erosion, allowing a cluster efficiency of +90% throughout the treatment stage

- There is no pressure communication with the annulus until BurstPoint port rupture pressure is reached

- No special cementing procedures are required

- The surface pressure performance indications are an accurate monitor system of the tool performance during the treatment

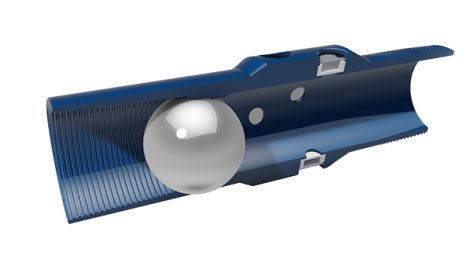

Ball -Drop Cemented initiation Sub

Overview

Our Completion Energy’s Ball-Drop, Cemented-Initiation Sub (Ball-Drop CIS) is a modification of the successful patented Completion Energy’s Cemented Initiation Sub. The Ball-Drop CIS incorporates a ball seat just above the standard BurstPoint™ ports. After the cement job is complete and the flow communication is re-established, the ball seat gives the ability to test the liner pressure integrity by just dropping a dissolvable ball from the surface.

APPLICATION

- A simple, reliable and rugged design for cemented liner installation applications

- Provides the ability to pressure test the liner prior to any stimulation operations

- Eliminates the use of coiled tubing and perforating costs for the first stage initiation in the plug-and-perf operation applications

- Can also be used as a flow path to initiate our Completion Energy’s cemented MultiFrac™ or EnerFrac™ ball-drop systems

- Can pump a full stimulation treatment through the BurstPoint ports for the first stage stimulation after the ball dissolves

FEATURES AND BENEFITS

- Provides increased operational efficiency resulting in reduced costs and higher well production perfomce

- The BurstPoint ports within the CIS can be sized to control the stimulation fluid rate

- Full drift inside diameter (ID) – eliminating drill out requirements

- No required special cementing procedures

- The surface pressure indication is an accurate monitoring system of the BurstPoint port opening

- Industry-proven dissolvable ball technique