Initiation Assembly

Overview

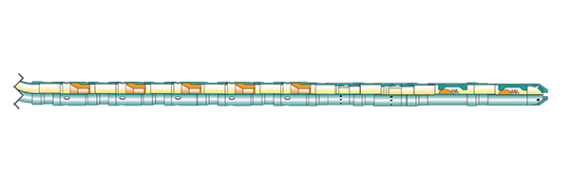

Tartan Completion’s Cemented Initiation Assembly enables operators to initiate stimulation operations through the toe and perform a full first-stage limited-entry stimulation in cemented wellbores. By combining Tartan’s patented Cemented Initiation Sub (CIS) and MultiFrac™ limited entry sleeves, the Initiation Assembly can be customized to the desired stimulation rate.

Since all tools — including the CIS — are incorporated into the stage design, no rock will go untreated. Because the toe stage will have the same number of points as a regular entry stage, there is no need to pump a smaller stage for the toe of the well or pump guns down to perforate the remainder of the toe/first stage.

The CIS and MultiFrac sleeves feature patent-pending BurstPoint™ ports that improve stimulation treatment placement and effectiveness and keep the system internals completely closed during installation and the cementing process, eliminating the risk of debris and cement invasion.

The MultiFrac hydro-mechanical sleeves are activated with standard or dissolvable balls and enable cluster stimulation by opening multiple sleeves with one ball. Once the sleeves are shifted, liner pressure is increased to fully open the BurstPoint ports to achieve calculated limited entry stimulation with +90% cluster efficiency.

APPLICATION

- Eliminates coiled tubing and perforating costs for first stage initiation in cemented wellbores

- Enables full stimulation and production of toe zone

- Efficient cluster stimulation of lower zones in extended reach laterals

- Ball-drop CIS option provides ability to pressure test the liner prior to stimulation operations

FEATURES AND BENEFITS

- Provides increased operational efficiency resulting in reduced costs

- BurstPoint ports can be sized to control the stimulation fluid rate on a per sleeve basis

- BurstPoint port inserts prevent erosion, allowing cluster efficiency of +90% throughout the treatment stage

- No communication with the annulus until BurstPoint port rupture pressure is reached

- No special cementing procedures required

- Surface pressure indications are an accurate monitor of tool performance