High-Performance open hole well completion systems

Simple, Reliable, Flexible

Completion Energy Multifrac™ Limited-Entry And Enerfrac™ Single-Entry System Can Also Be Run As Open Hole Completions

The same sleeve designs are utilized and run between Completion Energy’s Isolation Packers to provide the required isolation capability and achieve the desired stage number and density. Just pumping a ball to the Toe Circulation Sub will enable the pressure activation of the Isolation Packers and subsequent initiation of communication with the annulus via the Hydraulic Initiation Port.

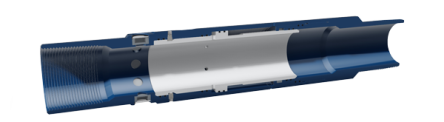

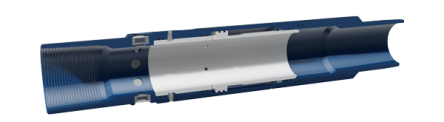

ISOLATION PACKER

- In unconventional completions, our packers reliably isolate the target zones during the open hole fracturing jobs

- During drilling operations, our packers provide a robust sealing of the formation ahead of the stage cementing, plug-and-abandonment, or sidetracking applications

- During completion operations, our open hole isolation packers can be deployed to isolate any gas cap, block off oil/water contact, and segment different horizontal production zones

- Specific products in the open hole isolation packer family include the Completion Energy, which uses a self-swelling elastomer element to close off any annular flow around your well and tubular assemblies. The seal self-energizes in all annular fluids, even any hydrocarbons.

- And for your deep, extreme-condition wells, the isolation packer eliminates annular flow and ensures a uniform production inflow along the lateral of your well. The packer gives you an assured, long-lasting seal in irregular open hole wellbore configurations, regardless of fluid type or temperature condition.

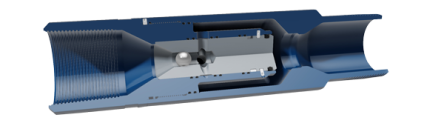

HYDRAULIC INITIATION PORT

OPERATION

The Hydraulic Initiation Port is positioned above the toe circulating sub and is actuated by creating a differential pressure after the toe circulating sub is closed. When the activation pressure is achieved, a sleeve shifts down opening the ports to establish communication with the formation. In the unlikely event that the sleeve does not shift, then the redundant BurstPoint port feature is used to establish the communication with the target zone.

- Incorporates a redundant BurstPoint port feature which activates the tool in the unlikely event the sleeve does not shift properly

- The activation is based on differential pressure, thus removing the need to account for wellbore dynamics

- It features adjustable activation shear settings

- Large exit ports allow high flow rates for the first stage stimulation operation

- The surface pressure indication is an accurate monitoring response of the tool activation mechanism

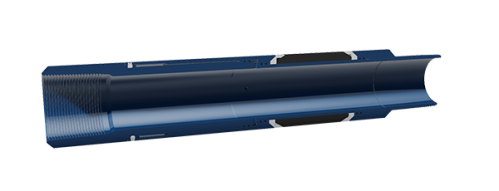

TOE CIRCULATION SUB

Completion Energy’s Circulation Sub (CS) is used to control flow between the completion string and annulus in all open hole multistage stimulation applications. By closing off flow with the annulus, the Toe Circulation Sub enables activation of tools in the completion string via hydraulic pressure.

The tool is activated by pumping an appropriate activation ball and is designed such that once activated, the ball is no longer needed to provide the seal.

OPERATION

The Toe Circulation Sub is positioned at the end of all open-hole stimulation system installations. A ball is pumped from the surface to activate and close the tool, which prevents any fluid flow to the annulus. The hydraulic pressure can now be increased to activate the tools along the completion string